The Tire & Plastics Recycling Technology aims for the production of specific products called "XYZ TM" (Trade Marked product).

The XYZ TM material has similar characteristics of Polymer. The XYZ TM is made by blending two recycled product (a) and (b), both products are obtained in most market by a special process:

Pure rubber crumbs, obtained from used tires by means of shredding tires in specific machine and equipment that are custom made for this purpose

The Primary Tire Recycling can be a standalone tire recycling system), truly a "Zero Pollution" process with NO emission of Sulfur, Zinc, etc. produces 99.9% pure rubber crumb up to 30- mesh.

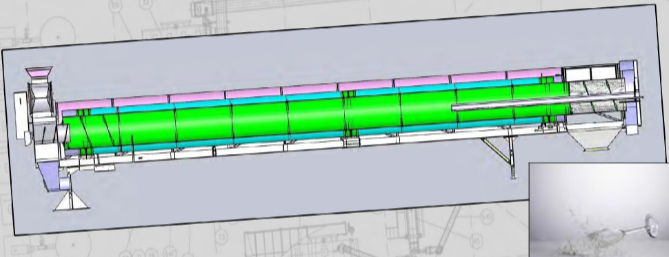

The shred is conveyed to a 53 ft. long Freeze Chamber, where it is pre-cooled as it enters from an airlock on the front and conveyed to the back end.

Liquid nitrogen is applied to the shred which freezes past its glass transition temperature of approximately The frozen rubber shred is crushed in very high tip speed Hammer Mills, further conveyed to a screen where the fiber is removed, while larger pieces of crumb are returned to the freezing chamber, the smaller crumb is then dried.

Steel is removed by a rare earth magnet and then the crumb is screened to select as many sizes as desired in a standalone system.

The Primary system provides the lowest life-cycle cost compared to any tire recycling system that can produce the same volume and same mix of outputs. The Primary system shall be integrated with a secondary process,

The Primary system shall be integrated with a secondary process,

The recycled plastic to be blended should be 100% high-density polypropylene (HDPE) or low- density polypropylene (LDPE) or polyethylene (PP).

There is no mix ratio – it would depend on the supplied customer specification to meet a typical blend would be rubber to rubber.

The characteristics of the HDPE, LDPE, PP input will likely be determined by a customer requirement for melt flow for example.

The input color of the recycled plastic really doesn't matter, the pellets produced will be grey/black due to the carbon black in the rubber, if client request to produce colored pellets we would need to control the plastic input color so as to add the appropriate amount of colorant to achieve the desired end color of pellet.

Combining crumb rubber with a thermoplastic binder using this Technology yields XYZ a material that can be processed more like a thermoplastic compound, but still has some of the elasticity of rubber. This is a very cost-effective method of producing high volume products such as acoustic insulation in cars, pallets, railroad crossings, etc.